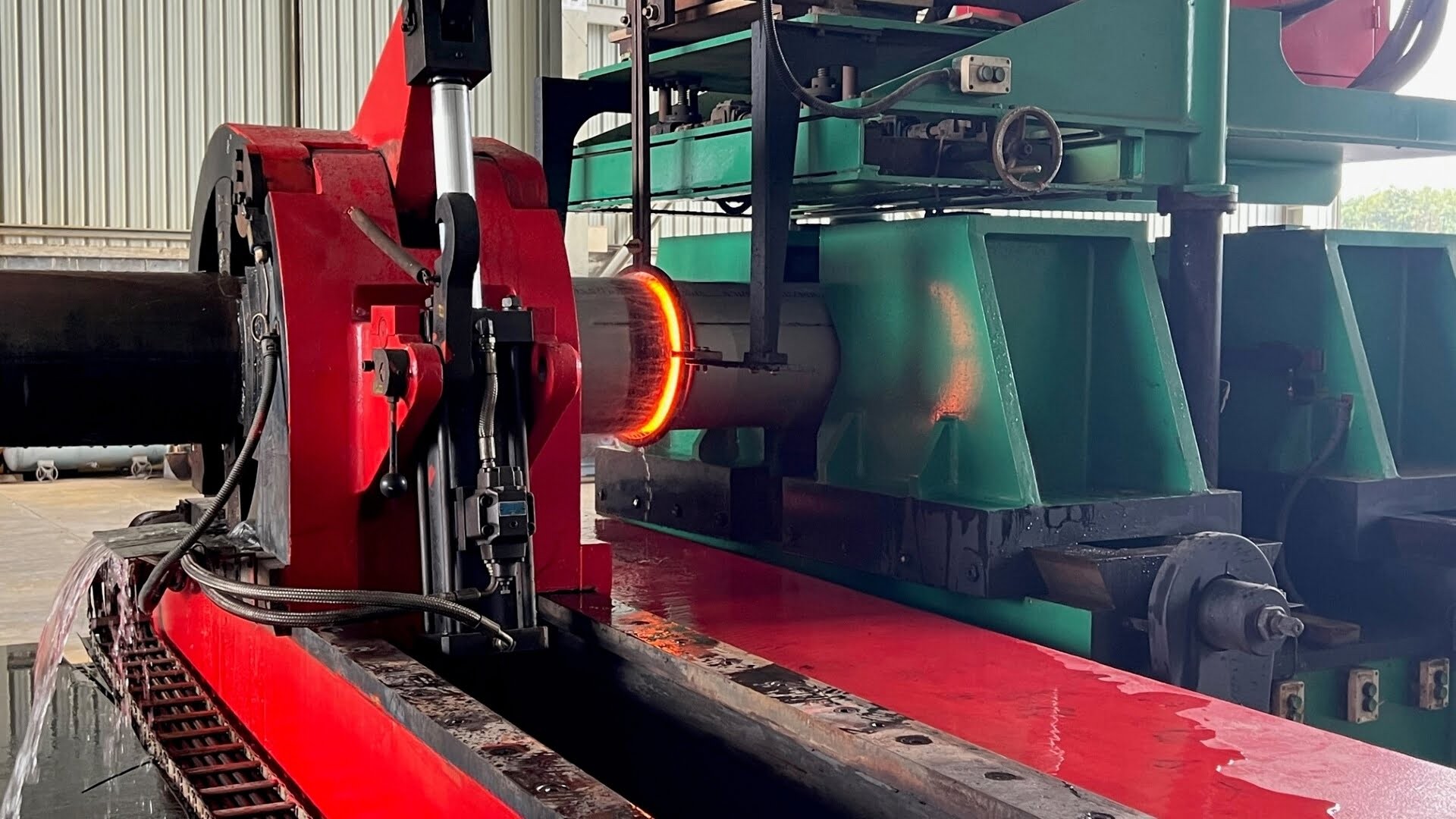

INDUSTRY QUALITY STEEL

FABRICATORS

Providing fabrication services to the Energy, Mining,

Chemical, Processing and Construction sectors.

/ K999 People

Offering a wide range of roles and career opportunities

We invest in our people at K999 Engineering and Construction and believe in core values as an employer.

/ Our Commitment

Listening to others to understand what is expected from us

Working efficiently focusing on what is important, we never compromise on quality or safety.

Who are our clients

“The supply and fabrication services provided to LOR was of a high standard, quality and professionalism.”

– Laing O’Rourke

Contact Us

ADDRESS:

174 Moo 5, Mapkha

Nikompattana, Rayong, 21180, Thailand

PHONE:

EMAIL: